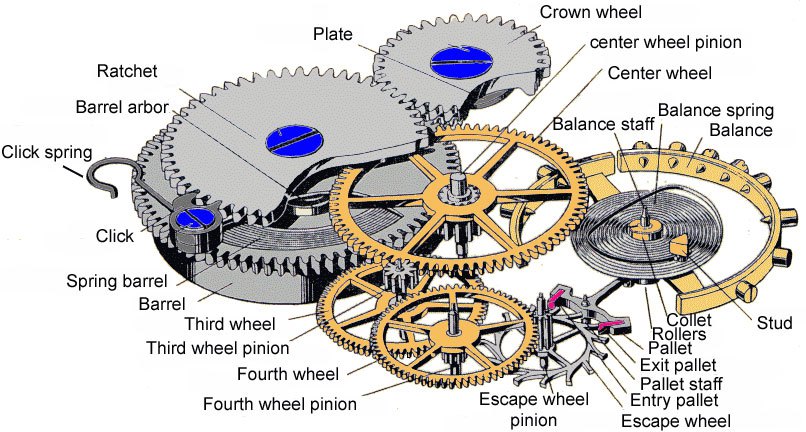

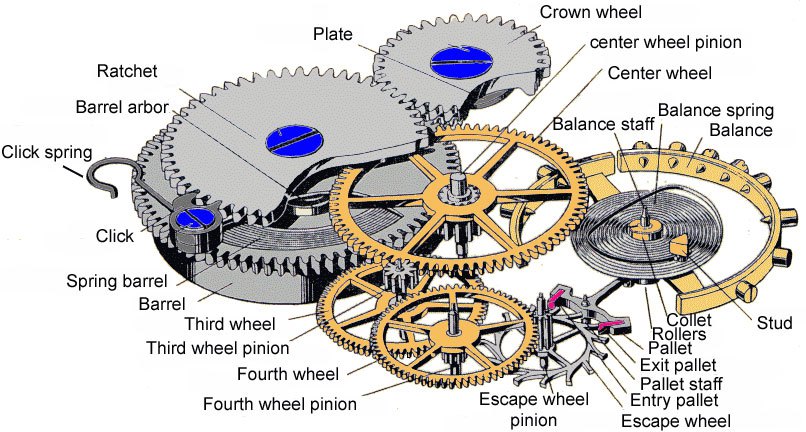

Going back the watches for a second, there's the gear train at the heart of the movement...I didn't remember this technical term, 'Optical train'...

Going back the watches for a second, there's the gear train at the heart of the movement...I didn't remember this technical term, 'Optical train'...

The differences are in the lenses themselves and these can be replicated. The problem is the perceived value of a Vortex as compared to a Swarovski/Leica/Zeiss binocular. Most people are not in a position to compare multiple binoculars before buying and it is safer to buy a top tier or a bottom tier binocular. In the middle ground are the Vortex binoculars that are made in Japan, Philippines, China, Taiwan and Korea, for this USA based company.The optical system in binoculars is easily visible in images and in cut through samples. And it's just to x-ray the tube to see how the optical system is designed.

Therefore, it should be easy for any manufacturer to copy any binocular they want. Is the exact optical design copyrightable? And if so: how closely is it permissible to imitate?

And why do we not see chinese replicas of the european and japanese high grade models, when luxuary watches of all brands are replicated?

I think it should have been juridical processes about this. Or?

Now it reads a little more accurately. Regardless of common misperception, no matter how many people buy things for appearance sake, there still remain many who don’t care what others think, with many of them still buy the nicer product, be it a car, house, watch or binoculars.Some guys will buy the less accurate Rolex to have a status symbol on their wrist.

Holger, can you shed some light on how expensive (and indeed possible) it might be to get uncoated and single-coated lenses/prisms multi-coated? How much tailoring of the coatings is needed to match the properties of the glass (and any existing coatings)? Would existing coatings need to be removed? I remember reading somewhere (but cannot recall the source - apologies) that going from single to multi-coatings helped increase brightness, but made things like chromatic aberration and colour rendition more challenging. I'd be really grateful for more insights into this.

You describe what is typical for most products..... Non- recurring costs upfront that need to be amortised over the early units.Several years ago, perhaps about 2010, I was in Kunming and had a conversation with one of the local binocular manufacturers. Among other things, I asked the manager whether it would be possible to create a clone of one of the classic binoculars, such as the Zeiss 8x60 or the SARD 6x42, upon request. He said no problem, if I arrange one original sample and add about 120.000 Euro, then within a couple of months they could design a prototype as closely as possible to the original (they would have to use modern glass types with similar properties as the vintage optical glasses, which are no longer made, and then re-compute the optical design). After the prototype is done, it would be up to me how to proceed. If I were willing to take something like 100 samples at least, they would start serial production, but the prices would turn reasonable only if 500 or more samples were made. In case the management would like the performance of the prototype and see some potential for a mass production, they would also consider to reimburse the initial investment and produce and distribute larger numbers on their own.

I guess that one should better have something close to half a Million $ available when embarking on such an adventure. Perhaps one could try a crowdfunding, but then, how many people would be crazy enough to go for it? If you find 100 participants, then you may still end up with something of the order of 5.000$ per sample, which would be on a similar level as the Nikon WX.

Cheers,

Holger

Cheap Chinese Conquest HD Vs a Japanese Opticron Aurora or GPO HD....Better things cost more to make than cheap things.

A cheap knock-off will never be the same as the real thing.

Better glass, better coatings, better materials, tighter tolerances and so on.

I have no clue, nor am I ever likely to.Cheap Chinese Conquest HD Vs a Japanese Opticron Aurora or GPO HD....

What has the Better glass, better coatings, better materials, tighter tolerances and so on ......?

Sounds like my Canon fast prime lens from the 70s/ 80s might be ☢️!Thorium glass stocks were disposed of by the British firms and the premises cleaned up.

Military thorium lenses were withdrawn and destroyed somehow.

There are now regulations regarding thorium lenses and existing units cannot officially be worked on by grinding etc.

There are also limits to how many thorium lenses can be stored together.

Horace Dall had a large slab of glass that was his optical flat.

It was grey and looked suspicious to me.

Next time I visited I monitored it and it was thorium glass.

It didn't bother him at all and remained on his work bench.

Crystal glass was 24% lead.

I don't know how modern crystal glass is made.

It was soft and easy to cut.

Old large magnifying glasses look green side on.

Regards,

B.

remove the original glass and insert modern glass with better properties. But would that have any appeal? The fun in vintage is the workmanship that you can feel when using the tool. But the buttery smooth re-greased focus wheel would remain; so would the ergonomics.

How close are the tolerences for classic Porros, with respect to how far apart each optical element needs to be from the next?