It's funny; no one's discussed the point raised by the individual I quoted - ie. that comparing "two binoculars of the same model—produced on the same day" is "impractical and foolish". Any thoughts/experiences? The problem of course is that most of us won't easily be able to try a meaningful number of samples of the same binocular model (and how many would that be? Probably 10 at a minimum, if not 20 or 30? I mean even alpha binoculars must be produced by at least a few hundred per year?) to make a really informed statement re sample variation.

-

Welcome to BirdForum, the internet's largest birding community with thousands of members from all over the world. The forums are dedicated to wild birds, birding, binoculars and equipment and all that goes with it.

Please register for an account to take part in the discussions in the forum, post your pictures in the gallery and more.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How much variation is there in the production line. (3 Viewers)

- Thread starter Paultricounty

- Start date

More options

Who Replied?To me , this whole question is rather silly.

1. when lens are ground in bulk, the edge ones are not as good as the centre ones.

They are all pretty good, but none are identical.

2. When polished they are all similar but not identical.

3. The thickness of the lenses are similar, but not identical.

4. The wedge of the lenses is small, but not identical.

5.The centration of the lenses is similar but not identical.

6. When the binocular is built, and this is important, the spacings are similar but not identical.

7. The alignments are good but not identical.

8. The different glass batches are similar, but not identical.

9. The coatings are similar, but not identical.

10. The mechanical parts are similar but not identical.

11. The designer, when he has done all the calculations, he then works on the tolerances.

12. These tolerances can either add up or cancel each other in umpteen different ways.

13. In actual testing of binoculars and even more so in spotting scopes, it is very clear that they are not identical.

Sometimes they are very close.

14. Some binoculars and spotting scopes are just not acceptable, even from top makes.

But apparently, the makers standards are just not very high.

Perfection does not exist, except in the mind, and even then it does not exist, as our minds are not perfect.

Regards,

B.

1. when lens are ground in bulk, the edge ones are not as good as the centre ones.

They are all pretty good, but none are identical.

2. When polished they are all similar but not identical.

3. The thickness of the lenses are similar, but not identical.

4. The wedge of the lenses is small, but not identical.

5.The centration of the lenses is similar but not identical.

6. When the binocular is built, and this is important, the spacings are similar but not identical.

7. The alignments are good but not identical.

8. The different glass batches are similar, but not identical.

9. The coatings are similar, but not identical.

10. The mechanical parts are similar but not identical.

11. The designer, when he has done all the calculations, he then works on the tolerances.

12. These tolerances can either add up or cancel each other in umpteen different ways.

13. In actual testing of binoculars and even more so in spotting scopes, it is very clear that they are not identical.

Sometimes they are very close.

14. Some binoculars and spotting scopes are just not acceptable, even from top makes.

But apparently, the makers standards are just not very high.

Perfection does not exist, except in the mind, and even then it does not exist, as our minds are not perfect.

Regards,

B.

elkcub

Silicon Valley, California

Please! Don't make me laugh. 😵Hopefully that's not an unwitting self-portrait.

henry link

Well-known member

You may not be able to compare two binoculars produced on the same day, but when you compare the two sides of one binocular you are almost certainly comparing two telescopes that were produced on the same day. Usually the two sides are not identical when examined closely and that allows the first step to be made toward understanding which defects come from the design and apply to all the telescopes of that binocular model and which are sample defects that apply to only some of the telescopes.It's funny; no one's discussed the point raised by the individual I quoted - ie. that comparing "two binoculars of the same model—produced on the same day" is "impractical and foolish". Any thoughts/experiences? The problem of course is that most of us won't easily be able to try a meaningful number of samples of the same binocular model (and how many would that be? Probably 10 at a minimum, if not 20 or 30? I mean even alpha binoculars must be produced by at least a few hundred per year?) to make a really informed statement re sample variation.

If, for instance, only one side of the binocular is astigmatic and only the other side has a blunt roof prism edge in a star test you can safely eliminate both of those as design defects since one telescope is free of each one. If both sides have excessive spherical aberration then that can't be eliminated as a design defect until a telescope without it is found.

I would be somewhat confident that any defect that turns up in both sides of a single binocular is probably a design limitation, more confident after the same result with two pairs and pretty certain after three. If astigmatism and blunt roof prism edges turned up in 5 out of the 6 telescopes in that group I would still know they're not design defects, but would be pretty confident that they are likely sample defects.

tenex

reality-based

Can you elaborate on that? I can't envision the bulk process you're describing.1. when lens are ground in bulk, the edge ones are not as good as the centre ones.

I wasn't sure I understood that bit several years ago, and still am not upon re-reading the post now. Everything else he said there acknowledged the sort of variation discussed here, so his point can't have been that you'd never notice any. It seems possible that he meant it was foolish to check for because of course there is such variation, though I don't see what's "impractical", as it can be useful to invistigate how much there is. But that's only a guess, so unless he wants to explain it himself, you could formulate some clearer proposition to discuss.It's funny; no one's discussed the point raised by the individual I quoted - ie. that comparing "two binoculars of the same model—produced on the same day" is "impractical and foolish".

elkcub

Silicon Valley, California

Returning to the OP's first post, he's basically referring to his own psychological perceptions. (Note: His earlier BF report, reminds us that MIG and MIP refer to Leica products made in Germany vs. Portugal. Good to know.)

1. Brighter: color

2. Sharper: Image

3. CA: Image/Color

4: Tint/Hue: Color

5. Edge fall off: Image

As I see it, boosted star testing basically reveals aberrations that relate to image formation as discussed by Henry above and in the attached summary by Warren Smith from "Modern Optical Engineering" (1990(. Measurable objective correlates of perceived color differences (brightness, hue, saturation), however, require additional analysis of full transmission spectra using the CIE color system discussed in the second attachment.

Ed

Note that his observations involve both (1) image forming and (2) color aspects of what is perceived.In this discussion I’m specifically talking about optics, not mechanics, there may be quite a bit more variation in mechanics than in the optics. This is an unscientific and mostly subjective observation , but the optics geek in me tries to get second and third opinions before I go run my mouth.

I’ve compared with others, four Swaro 8x32 EL’s, one was clearly brighter and sharper. Compared three Leica 10x42 Trinovid HD’s , one clearly had less CA. Compared three Zeiss SF 8x42, one clearly had a greener color tint/hue. Now that I’m thinking about it , three Kowa Genesis, one clearly had more edge fall off. Also tried over half dozen 8x42 Leica UVHD+’s side by side , this was put together after someone here made multiple comments over a period of weeks about the MIG was better than MIP, not so , the surprise here was there no variation noticeable in any of those samples.

1. Brighter: color

2. Sharper: Image

3. CA: Image/Color

4: Tint/Hue: Color

5. Edge fall off: Image

As I see it, boosted star testing basically reveals aberrations that relate to image formation as discussed by Henry above and in the attached summary by Warren Smith from "Modern Optical Engineering" (1990(. Measurable objective correlates of perceived color differences (brightness, hue, saturation), however, require additional analysis of full transmission spectra using the CIE color system discussed in the second attachment.

Ed

Attachments

Last edited:

elkcub

Silicon Valley, California

Yes, you did miss something.I don’t see how perceived color differences can be described as “objective”.

Did I miss something?

In an effort to simplify. Suppose N = j people wish to discuss the distance between two objects on the ground. One way is for each person to walk heel-to-toe from one object of the other and announce there are Xj feet separating them, j referring to the particular person. The conversation would be nearly meaningless because each of the j individuals has a different, i.e., subjective, foot size. If instead they used a tape measure, then the distance could be discussed without a problem because they would all using the same 'standardized' foot as a reference.

Ed

For the British standard audience.

Last edited:

Paultricounty

Well-known member

Excellent info Ed, thank you. Correct me if I’m wrong, when comparing these low magnification , in this case high quality multiple (just a few) examples of binoculars, the eye really can’t see the actual optical superiority from one another. We really can’t see which one is corrected better. That we can only see slight variations which may have no meaning ( color tone, brightness etc. etc.) whatsoever with the optical level of the optic ?Returning to the OP's first post, he's basically referring to his own psychological perceptions. (Note: His earlier BF report, reminds us that MIG and MIP refer to Leica products made in Germany vs. Portugal. Good to know.)

Note that his observations involve both (1) image forming and (2) color aspects of what is perceived.

1. Brighter: color

2. Sharper: Image

3. CA: Image/Color

4: Tint/Hue: Color

5. Edge fall off: Image

As I see it, boosted star testing basically reveals aberrations that relate to image formation as discussed by Henry above and in the attached summary by Warren Smith from "Modern Optical Engineering" (1990(. Measurable objective correlates of perceived color differences (brightness, hue, saturation), however, require additional analysis of full transmission spectra using the CIE color system discussed in the second attachment.

Ed

In my examples/subjective tests (in most cases) I do this with multiple people (with different shoe sizes I guess 😜) all coming up with the same measurement. I already stated that the test is very unscientific. What we try to do is to write down 3-4 things to look for in each binocular, which we number on paper. Then we hand them back and forth for people , to write down there observations on each, we might do this under two or three different lighting conditions throughout a day or more, then we all compare notes later in in the day (or when completed) over a coffee, or with something stronger.

The consensus isn’t always 100% of course, but it definitely is conclusive. When we have 5 people say binocular #3 is brighter than the others, it’s telling me something. To summarize if I understand you correctly this isn’t saying anything, that one is slightly better than the other optically, it just means one is standing out slightly in some optical trait than the other. We could even say that if we looked for the least bright binocular, that one possibly could be the best corrected specimen, yet most likely every time the individual might not pick that one for themselves. Am I making any sense here?

Paul

Post #45.

On YouTube if you put 'Bulk lens polishing' various videos come up.

I got Shanghai Optics, which shows about 20 small lenses being ground and polished at one time.

With objective lenses it may be they are still made one at a time, I don't know.

But smaller lenses and prisms are made about twenty at a time.

There are problems nowadays.

In some cases I think that molded glass banks are just polished without grinding..

High speed polishing may be used, but I am told that high speed polishing although quick, does not produce the quality of traditional polishing.

Also with bulk polishing the small lenses, maybe twelve around the outside are not as good as the central ones.

I doubt that hand finishing is done on commercial spotting scopes.

The very best telescopes and lenses are hand finished by master opticians.

What surprises me is how good low priced astro telescope optics are from China and Taiwan, with some exceptions.

But nowadays speed and cutting corners, especially with mechanical components seem to be the business model, with quality control left to the buyer, who often doesn't have a clue.

Regards,

B.

.

On YouTube if you put 'Bulk lens polishing' various videos come up.

I got Shanghai Optics, which shows about 20 small lenses being ground and polished at one time.

With objective lenses it may be they are still made one at a time, I don't know.

But smaller lenses and prisms are made about twenty at a time.

There are problems nowadays.

In some cases I think that molded glass banks are just polished without grinding..

High speed polishing may be used, but I am told that high speed polishing although quick, does not produce the quality of traditional polishing.

Also with bulk polishing the small lenses, maybe twelve around the outside are not as good as the central ones.

I doubt that hand finishing is done on commercial spotting scopes.

The very best telescopes and lenses are hand finished by master opticians.

What surprises me is how good low priced astro telescope optics are from China and Taiwan, with some exceptions.

But nowadays speed and cutting corners, especially with mechanical components seem to be the business model, with quality control left to the buyer, who often doesn't have a clue.

Regards,

B.

.

John A Roberts

Well-known member

John A Roberts

Well-known member

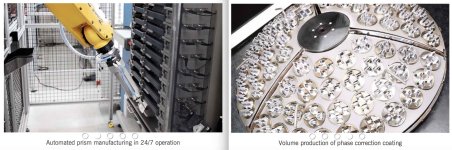

And images of automated and bulk production of prisms, from Swarotec: Home:

Besides manufacturing it's own optics, Swarovski Optik also produces optical components and products for others under the Swarotec brand.

See two known examples in post #7 at: Swarovski Binoculars - Volume of Production

John

p.s. In terms of modern production processes, Meopta offers a wide variety of services.

See a set of screens starting at: Industrial & OEM | Meopta :: Better view of the world

The Manufacturing screen flow (under 'Meopta key services') will probably be of most interest.

(and for those with sufficient technical knowledge, the flow under Measurement & Testing may also be of interest).

And a 16 page brochure, concentrating on the technologies used for the production of optics such as binoculars

(including quality control), can be found under 'Brochures and catalogues' at: Download | Meopta :: Better view of the world

Click on Technological Capabilities.

Besides manufacturing it's own optics, Swarovski Optik also produces optical components and products for others under the Swarotec brand.

See two known examples in post #7 at: Swarovski Binoculars - Volume of Production

John

p.s. In terms of modern production processes, Meopta offers a wide variety of services.

See a set of screens starting at: Industrial & OEM | Meopta :: Better view of the world

The Manufacturing screen flow (under 'Meopta key services') will probably be of most interest.

(and for those with sufficient technical knowledge, the flow under Measurement & Testing may also be of interest).

And a 16 page brochure, concentrating on the technologies used for the production of optics such as binoculars

(including quality control), can be found under 'Brochures and catalogues' at: Download | Meopta :: Better view of the world

Click on Technological Capabilities.

Last edited:

Users who are viewing this thread

Total: 4 (members: 0, guests: 4)